SUPER NOVA

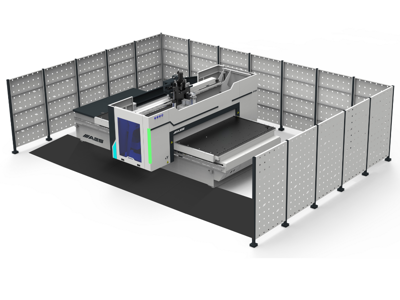

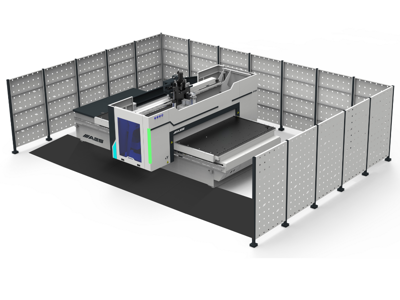

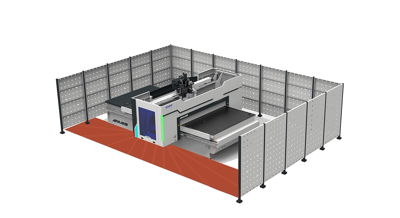

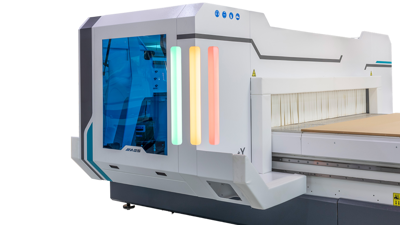

Le Super Nova est un centre d'usinage CNC à 3 axes nesting qui offre la souplesse d'utilisation nécessaire grâce à la gamme de changeurs d'outils, au grand choix de moteurs de fraisage refroidis par air ou par liquide et à la table matricielle HPL divisible en 18 zones de vide.

Avec une précision d'usinage impressionnante, cette machine garantit des résultats de fraisage et de perçage parfaits à chaque fois.

La commande est simple grâce à une technologie CNC de pointe avec le logiciel NC-Hops en standard.

La machine idéale pour les entreprises du secteur de la construction intérieure qui apprécient la flexibilité tout en ayant la productivité nécessaire pour un budget très attractif.

SUPER NOVA

Zurück zur ÜbersichtLa technologie CNC Nesting à un prix raisonnable, c'est ce que représente la Super Nova. Avec son design standard très spacieux, elle est accessible à tous ceux qui recherchent une machine CNC Nesting à part entière, avec la puissance et la rentabilité nécessaires. Combinant la technologie Nesting avec des performances de pointe, la Super Nova réussit à merveille.

Cette machine peut devenir le cœur de vos opérations d'usinage dans votre atelier. L'interface utilisateur très intuitive et la disposition logique des éléments de commande garantissent une intégration parfaite dans votre activité. La commande via des systèmes CAD/CAM externes peut être parfaitement intégrée. L'automatisation ou l'intégration dans des environnements de production déjà automatisés ne pose aucun problème. Fiabilité, puissance et haute technologie moderne.

Qu'il s'agisse de fabrication sur mesure ou de production en série, Super Nova fonctionne toujours.

Die wichtigsten Highlights auf einen Blick

- Construction portique

- Dimensions du zone de travail disponibles: 1325 / 1336 / 1632 / 1640 / 2128 / 2132 / 2136 / 2142 / 2157

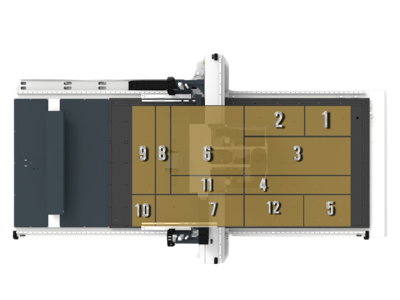

- Zones de travail séparables jusqu'à 18 zones d'aspiration

- Logiciel d'exploitation très convivial

- Lubrification centrale

- Système de mesure automatique de la longueur des outils

- Nombreuses options d'automatisation

- Rapport qualité-prix excellent

Les machines AES se caractérisent par une construction extrêmement solide et l'utilisation des technologies les plus récentes.

Grâce à leur large gamme, vous trouverez une machine adaptée à chaque application.

Unsere Showroom

Besuchen Sie unseren großzügigen Showroom mit 1600 m² in Hooglede, in dem alle unsere CNC-Maschinen und Kantenanleimmaschinen einsatzbereit für Live-Demonstrationen zur Verfügung stehen. Erleben Sie die Qualität, Geschwindigkeit und Präzision unserer Lösungen aus nächster Nähe. Unsere Experten stehen Ihnen mit persönlicher und professioneller Beratung zur Seite.

SUPER NOVA: Technische daten

- Brug-type machine

- Werkveld: breedte Y=1300 mm, lengte X=2500 / 3600 mm en werkbereik Z=200 mm

- Werkveld: breedte Y=1600 mm, lengte X=3200 / 4000 mm, en werkbereik Z=200 mm

- Werkveld: breedte Y=2100 mm, lengte X=2800 / 3200 / 3600 / 4200 / 5700 mm en werkbereik Z=200 mm

- Snelheden: Y= 70m/min., X= 70m/min., Z= 20m/min.

SUPER NOVA: Details

The central lubrication system provides various guides with a controlled dose of lubricant.

Periodic lubrication increases the lifespan.

This helps prevent malfunctions and boosts productivity.

With this handheld terminal, you can manually move the three axes individually using the handwheel at three different speeds.

An emergency stop button is also provided.

The handheld terminal is used to control the machine axes outside the control

panel in manual mode. Machine operating speeds and parameters can be

controlled with the help of the terminal. In addition, with the help of a handheld

terminal, general commands can be controWith this handheld terminal, you can independently move the three axes with infinitely adjustable speed using a potentiometer while running a program.

If the CNC machine is equipped with a Label X station, its speed can also be infinitely controlled via a second potentiometer.

Additionally, in manual mode, some general commands can be controlled outside the control panel, such as tool changes, vacuum pumps, and the position of the extraction hood.

An emergency stop button is also provided.lled with the help of tool change,

vacuum zone control & dust collection.

.png?width=400)

This CNC machine can be equipped with different types of milling motors with ceramic bearings, available in air- or liquid-cooled versions:

• 9 kW (12 HP), ISO-30 / HSK-F63

• 12 kW (15 HP), HSK-F63

• 14 kW (19 HP), HSK-F63

All types of milling motors are equipped with a pneumatically height-adjustable extraction hood.

Depending on the number of tools in your workshop, you can equip your CNC machine with an 8-, 12-, or 16-position rotary tool changer.

The rotary tool changer moves along the X-axis, and all positions are equipped with an anti-crash control sensor to ensure a smooth tool change.

The machine is standard equipped with a preparation to manually pick up aggregates in pre-set positions, in accordance with the selected aggregate with a specific operation.

This CNC machine is equipped standard with a sturdy drilling head DH9:

- In the X-direction: 5 spindles

- In the Y-direction: 4 spindles

The automatic control of the extraction nozzle alternately allocates the full extraction power to either the drill head or the milling unit, depending on the active unit.

This ensures an optimal and efficient extraction result.

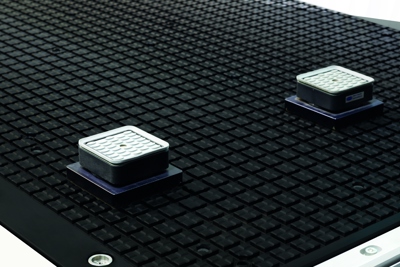

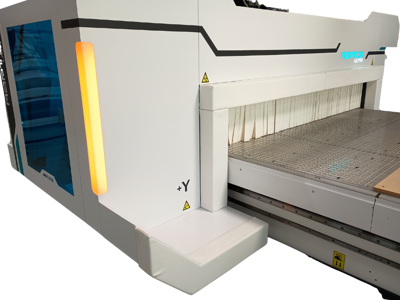

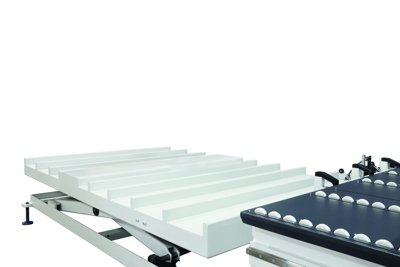

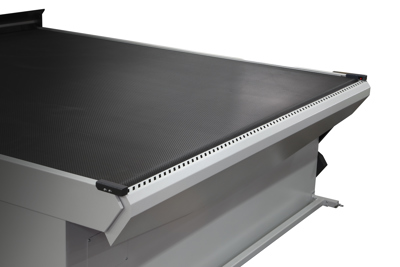

The High Flow matrix grid table is made of wear-resistant HPL (High Pressure Laminate).

The 30 x 30 mm grid is equipped with additional grooves that ensure a higher vacuum flow, resulting in optimal fixation of your workpieces.

This matrix grid table also allows working with specific vacuum cups, providing greater processing flexibility.

Multiple vacuum zones are automatically controlled according to the size of the panel.

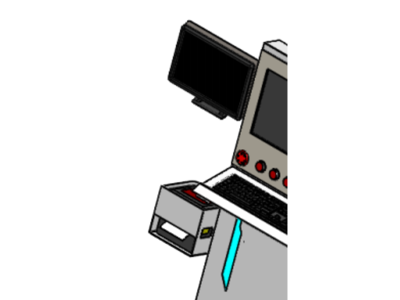

A user-friendly 21" flatbed color screen and all essential control buttons, integrated into the compact electrical cabinet of the CNC machining center, provides the operator with direct control and monitoring of the machine functions.

The modern, ergonomic, movable flatbed control console integrates both a 21” color screen and all essential control buttons.

The machine status is clearly indicated by large side LED color strips.

When entering the length dimension of new or re-sharpened tools, the machine places the tool on a calibrated measuring surface.

The measured actual value is compared with the theoretically entered value and is automatically adjusted in the tool library.

This results in highly precise machining operations.

.png?width=400)

This CNC machine can be equipped with one or more vacuum pumps.

The available options are:

• 140 m³/h

• 250 m³/h

• 300 m³/h

The vacuum zones of a CNC nesting machine are designed according to the work area dimensions and the most common sheet formats, ensuring both large and small sheets are securely and efficiently held in place.

The VACUBOOST system uses two vacuum pumps. The first pump keeps the workpiece securely in position. During machining, the milling cutter moves across the table from one vacuum zone to another.

The second pump, through the intelligent VacuBoost system, provides an additional concentrated vacuum precisely where the milling head is performing the operation.

Klicken Sie unten auf den Newsletter, um weitere Informationen zu erhalten:

NC Hops CAD/CAM user interface in combination with the AES PLC for axis control.

Easy graphic programming of workpieces.

Graphic representation of workpiece, machine details, clamps, ect possible.

Import of .DXF, .STL, .STEP drawings possible.

Including 3-D simulation and collision

control

The operator can easily control the machine via a 21" touchscreen. This screen supports the physical buttons and provides a visual and intuitive way to enter machining programs, adjust settings, and monitor the machine.

Closed cable chains ensure that dust and chips are kept out of the cable chain.

This provides extra protection for the electronic cables inside the cable chain against aggressive dust released during the processing of special materials.

Extra protection for guides and bearing blocks through an additional seal mounted on the bearing blocks, which retains the lubricant better inside the bearing block and keeps dust out more effectively.

A barcode scanner on a CNC machining machine is used to quickly and accurately select workpieces in a program database. By scanning barcodes, the correct machining information is automatically loaded, reducing errors and increasing efficiency. This contributes to an automated and streamlined production process.

A manual labeling unit on a mobile control console of a CNC machining center is used to manually apply labels to workpieces. This ensures clear identification and traceability within the production process, reducing errors and increasing efficiency.

Consists of an additional touchscreen for workpiece selection and a label printer.

The tool is cooled using compressed air during the machining of specific materials such as plastic, aluminum, etc.

This improves machining quality and extends the tool's lifespan.

An additional second zero point at the front right is extremely practical for positioning smaller workpieces on the machine table.

Includes additional stop cylinders and software adjustment.

This horizontal light curtain detects interruptions in the light beams and stops the machine when an object or person is detected.

A light curtain is a safety feature consisting of a transmitter, a receiver, and non or multiple mirrors, which together create an invisible safety barrier around the machine.

This light curtain detects interruptions in the light beams and stops the machine when an object or person is detected.

.png?width=400)

Contact mats at the front of the CNC machining center serve as an essential safety system.

When touched, they detect the presence of a person or object and immediately stop the machine.

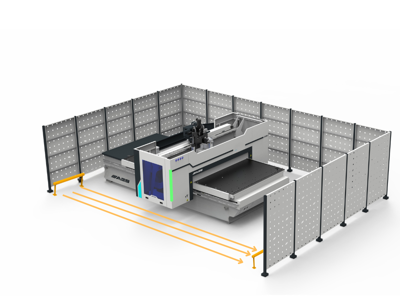

The fencing provides a robust enclosure on maximum of 3 sides of the CNC machining center.

The open side is equipped with another safety system of choice, in according with CE regulations.

This prevents the operator from unintentionally entering the danger zone of the machine.

Of course, it is possible to provide a safety door in the fence to allow controlled access to the machine.

Pressure cushions, at the front and/or rear, of the CNC machining center serve as an essential safety system.

When touched, they detect the presence of a person or object and immediately stop the machine.

A security system with a zone scanner is an advanced safety solution for CNC machining centers. The scanner, mounted on the chassis, detects people or objects within the safety zone of the scanner. This ensures a safe working environment without physical barriers, improving accessibility and efficiency.

A solid table on the infeed side of the nesting cnc machining centre equipped with an HPL top.

This table is suitable for plate per plate loading, manual or an automatic system.

A full pack of panels can be easily placed on this hydraulic lift table using a forklift, thanks to the cross beams.

Alignment stops in the Y-direction and a corner stop ensure precise positioning of your panel for processing.

Vertical alignment studs with steel rollers ensure a smooth transfer of panels from the lift table to the nesting table.

They also reduce the risk of panel damage.

Thanks to the alignment robots, the alignment process runs smoothly without operator intervention.

The robots ensure that the panel is precisely aligned against the vertical studs with steel rollers.

It is also possible to expand the number of vertical stud.

The loading unit, mounted on the machine bridge, transfers the panel from the infeed table to the nesting table using multiple vacuum suction cups. This ensures a smooth material transfer within the CNC nesting machining center.

After machining, the push-off and cleaning unit (mounted on the the machine gantry) removes dust from the workpieces and transfers them to the outfeed conveyor.

The conveyor belt transports finished parts from the machine to the operator.

This ensures the efficient and orderly disposal of parts, keeping the production flow running smoothly.

The label printer at the outfeed conveyor is used to manually apply labels to workpieces. This ensures clear identification and traceability within the production process, reducing errors and improving efficiency.

Consists of an additional touchscreen for workpiece selection and a label printer.

Möchten Sie weitere Informationen zu SUPER NOVA erhalten?

Zeugnisse

Die Bearbeitung unserer technischen Kunststoffe auf der CNC-Maschine AES läuft reibungslos. Wir sind sowohl mit der Maschine als auch mit dem Service von DB&S machines sehr zufrieden!

Bouffara Hakim

Seracraft

AES Super Nova 2132 CNC nesting center

Der Faktor DB&S Maschinen war bei unserer Wahl sehr wichtig, weil man einen Kauf auf der Grundlage von Vertrauen tätigt. Die jahrelange Zusammenarbeit hat uns überzeugt, eine AES Nesting CNC Produktionliniën Extreme Ultra zusammen mit DB&S Machines zu wählen.

Danny Goossens

Gopa Keukens

AES Extreme Ultra Nesting CNC Produktionliniën

Verpassen Sie nichts und verfolgen Sie unsere neuesten Nachrichten!

- Inspiration und Ideen!

- Immer die neuesten Informationen über unsere Maschinen

- Alle Details zu unseren Infotagen und -abenden

/Super%20nova%20met%205P.png?width=908)