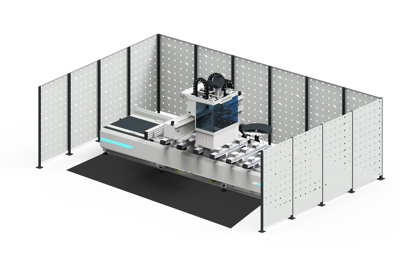

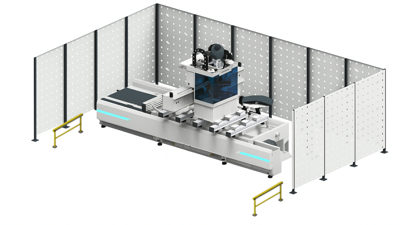

VEGA PRO

Back to overviewCNC technology in affordable form, that's what the Vega Pro stands for. With its very generous standard version, it is accessible to anyone looking for a fully-optimised CNC machine for universal and flexible work.

Combining CNC technology with top performance, the Vega Pro succeeds wonderfully. This machine can become the heart of your machining operations in your workshop.

The highly intuitive user interface with logical arrangement of the operating elements ensures flawless integration into your operation. Control by external CAD/CAM systems can be perfectly integrated.

Fitting the machine into automated projects is no problem either.

Reliable, powerful, modern high-tech and yet individually customisable if required.

Made-to-measure or serial work, even at industrial level, the Vega Pro is always right for you.

Key highlights at a glance

- Very robust construction for maximum stability and precision

- Gooseneck-type machine

- X-axis operating lengths 2500 / 3200 / 4500 / 6000 mm

- Very easy-to-use operating software

- Extended drill head DH17

- Automatic centralised lubrication

- Automatic tool length measuring system

- Unbeatable value for money

AES machines are characterised by extremely solid construction and use of the latest technologies.

Thanks to the wide range, there is the right machine for every application.

Our showroom

Visit our spacious 1,600 m² showroom in Hooglede, where all our CNC machines and edge banders are fully set up and ready for live demonstrations. Experience the quality, speed, and precision of our solutions up close. Our experts are ready to provide you with personal and professional advice.

/VEGA%20PRO_.png?width=908)

.png?width=400)

.png?width=400)