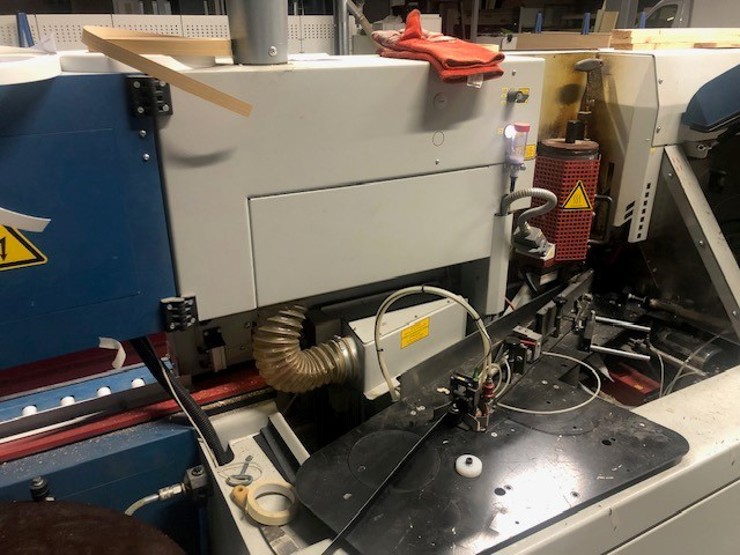

Edge banding machine OTT Twister

M002730/M002730%20OTT%20Twister%20used%201.jpg?width=928&height=440&bgcolor=fff)

Technical Data

Edge gluer working from right to left.

Gluing veneer and formica strips, mellamine, PVC on roll and solid edges.

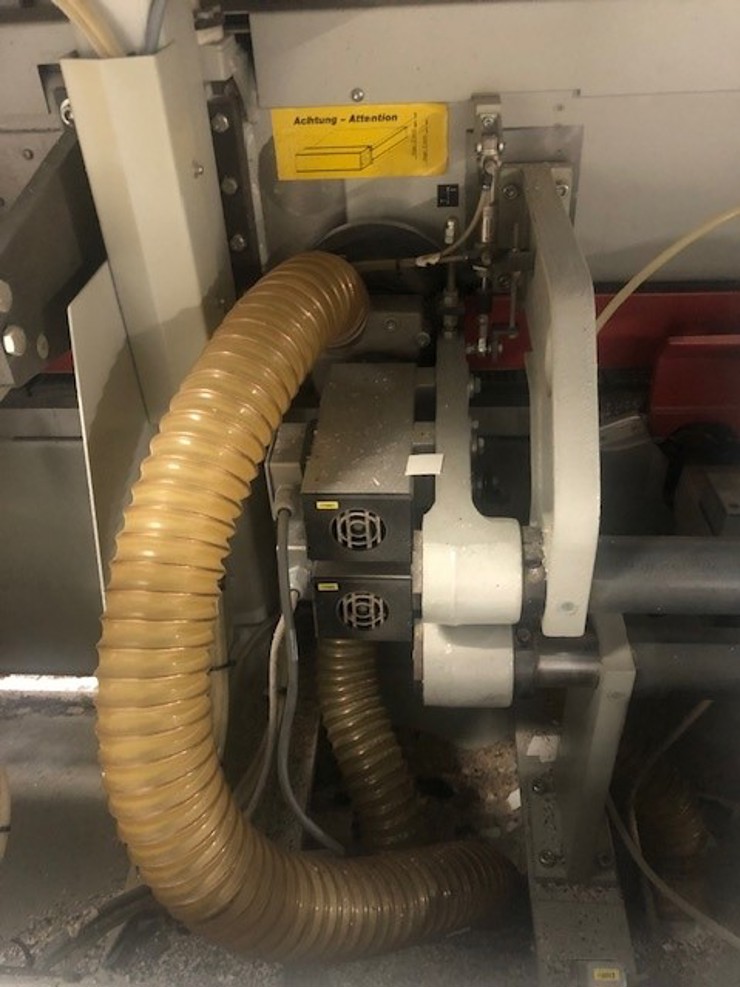

Processing of EVA and PUR glue, combimelt system (2.5 l glue tub)

Additional glue tub for processing PUR glue 2 kg blocks

Quick-change system of glue head and glue tray

Edge thickness: 0.4 - 10 mm

Feed magazine for strips or solid laths

Workpiece dimensions :

* minimum width : 70 mm

* minimum height : 8 mm

* maximum height : 60 mm

* minimum sheet length : 150 mm

Variable throughput speed : 14 - 20 m/min.

Automatic lubrication of the transit chain.

Upper pressure bar with flat belt and electronic positioning.

BECKHOFF Industrial PC with 15" colour touch screen.

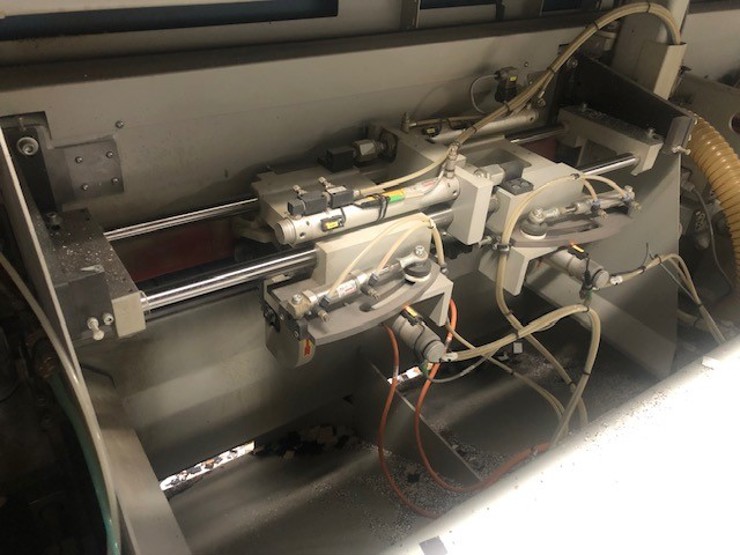

All units are pneumatically controlled from the switchboard.

No manual adjustment to edge thickness required due to adjustable

and automatic feed line

Automatic recognition of machining operations from CNC centres

Adapted probes for processing overhanging sheets

Heated feed guide

Swing-out feed roller table for narrow panels

Pre-milling unit :

2 HF motors travel and counterflow, automatically controlled height 62mm

Cutting to sheet length front and rear, bevel adjustment 0-5°

Flat milling above and below

Fine milling above and below

Radius milling from 1 to 3 mm

Radius scraper unit

Postform milling,

2 individually working units. (top/bottom)

2 HF motors

Additional radius scraper

Flat scraper unit

Anti-static nozzles

Glide nozzles

PUR cleaning set with 4 nozzles and brushes

Extraction nozzles : 1x diam. 100 + 1 x diam.200mm

Electric power : 23 kW - 45A 400V 50Hz 3Ph

Required air pressure : 6 bar

Machine dimensions (l x w x h) mm : 7300 x 1100 x 1600mm

Working height : 880 mm

Weight : 3250 kg

Similar used machnies

/4.jpg?width=376)

Edge banding machine Format 4 Tempora 60.12 E-Motion

M002421

/1.jpg?width=376)

Edge banding machine Homag Optimat KAL 310

M002621

/M002707%20Biesse%20Roxyl.jpg?width=376)

Edge banding machine Biesse Roxyl 5.50

M002707

Similar new machnes

/Ott%20Tornado+%20zonder%20achtergrond.png?width=376)

Tornado+

Compact, versatile edge-banding machine

- Feed speed 12 to 18 m/min

- Workpiece height 8 -60 mm

- Edge thickness 0,3 - 15 mm

- 3 trimming units : rough - radius - rounding

/Ott%20Storm+zonder%20achtergrond.png?width=376)

Storm+

Fast, versatile edgebander

- Feed speed 12 to 20 m/min

- Workpiece height 8 -60 mm

- 3 trimming units : rough - radius - rounding

- Automatic 2 Positon scraper

/OTT%20Pacific%20+%20zonder%20achtergrond.png?width=376)

Pacific+

Edge bander compact and flexible

- Feed speed 12 to 18 m/min

- Workpiece height 8 -60 mm

- Edge thickness 0,3 - 15 mm

- 2 trimming units : rough and radius+rounding

/M002730%20OTT%20Twister%20used%201.jpg?width=740)